Release Date: 2025-11-06 View Count:

FTTH Procurement Plan & Network Structure — Shenzhou Cables

Practical guidelines for sourcing, building, and accepting a high‑reliability FTTH network (GPON/XGS‑PON)

Executive Overview

This document describes a complete procurement strategy and a reference FTTH (Fiber‑to‑the‑Home) network structure for residential and mixed‑use deployments. It covers the end‑to‑end architecture (central office to ONT), bill of materials, vendor qualifications, quality control, logistics, acceptance testing, and risk management. Specifications reflect Shenzhou Cables’ manufacturing capabilities and field‑proven best practices used by global service providers.

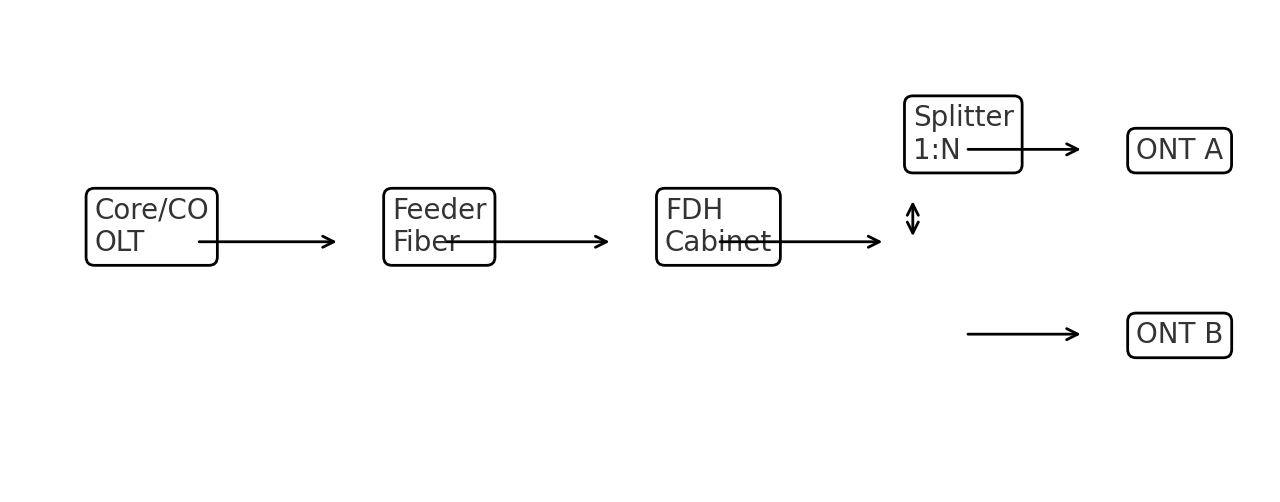

• Core/Backbone → Central Office (CO) with OLT shelves

• Feeder Network → ODF/patch panels, fiber management, and protected feeder cables to Fiber Distribution Hubs (FDH)

• Distribution Network → Passive splitters (1:8–1:64) in FDH or street cabinets, distribution cables to access points

• Drop Network → Outdoor/indoor drop cables to Customer Premise Equipment (ONT), via Customer Terminal Boxes (CTO/CPE box)

• Customer Premise → ONT/ONU, Wi‑Fi router, power supply, and optional battery backup

• GPON (ITU‑T G.984): 2.5 Gb/s DS / 1.25 Gb/s US; typical split 1:32–1:64

• XGS‑PON (ITU‑T G.9807.1): 10 Gb/s DS / 10 Gb/s US; typical split 1:32–1:64

• Optical budget classes: B+, C+, N1/N2; final selection based on outside‑plant lengths, splices, and connector counts

• Keep feeder routes as straight as possible; minimize splice points and bend events

• Engineer for ≥3–6 dB design margin beyond calculated losses

• Respect minimum bend radii (e.g., G.657.A1/A2 for tight indoor routing)

• Reserve spare fibers and splitter capacity (~20–30%) for growth and restoration

• Standardize on SC/APC for PON to reduce back‑reflection

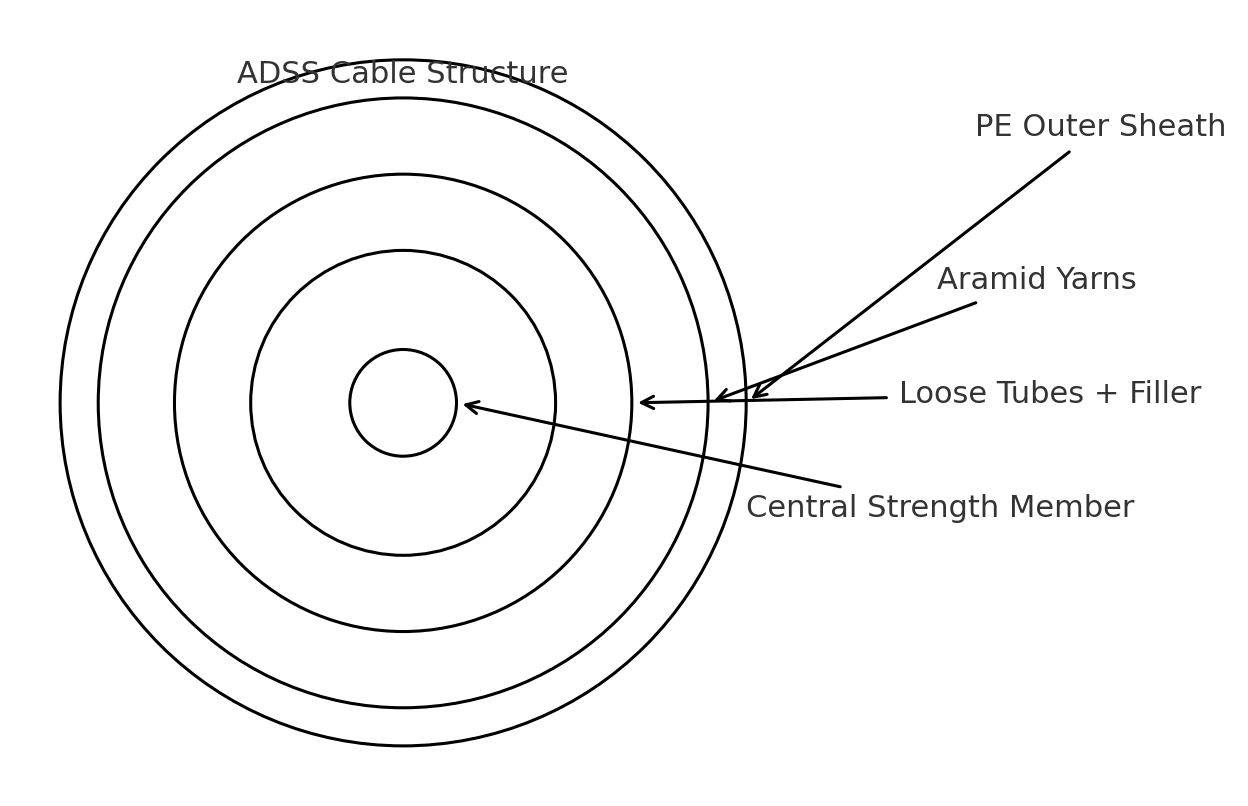

Feeder Cables (OSP):

• Single‑mode G.652.D or G.657.A1 loose‑tube, ADSS or duct‑grade

• Sheath: PE (UV‑resistant), dielectric strength members; optional AT sheath for anti‑tracking in HV corridors

Distribution Cables:

• 12–144F loose‑tube or micro‑cables, LSZH for indoor transition

Drop Cables:

• 1–4F flat or round, bend‑insensitive G.657.A2; outdoor LSZH/PE sheath; indoor LSZH

Splitters:

• 1:8/1:16/1:32/1:64 PLC, G.657.A1 pigtails, connectorized SC/APC or bare‑fiber in trays

Passive Hardware:

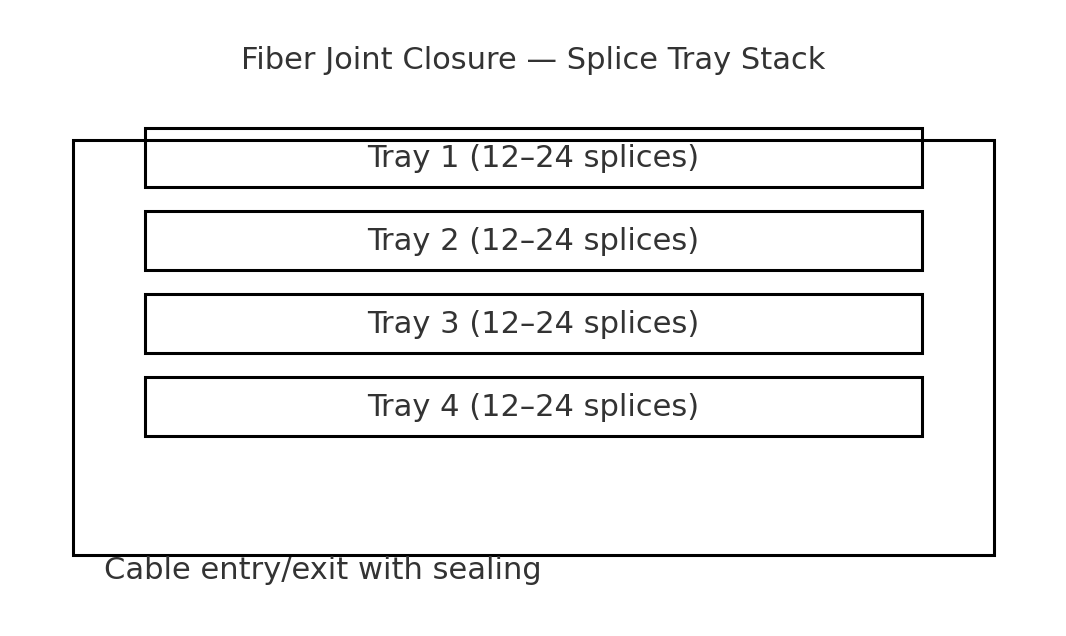

• FDH cabinets (IP54+), closures (dome or in‑line), splice trays, fiber management, distribution boxes, CTOs

WP1 Materials (Cables & Passive Hardware), WP2 Actives (OLT/ONT), WP3 Tools & Test Equipment, WP4 Logistics & Packaging, WP5 Documentation & Training. Each WP includes delivery milestones, QA/QC gates, and acceptance criteria.

The following table lists core line items. Quantities are estimated using the formulas provided in Section 14.

|

No. |

Category |

Item / Description |

Key Specs |

Unit |

Est. Qty (Formula) |

Notes |

|

1 |

Feeder Cable |

ADSS/OSP Loose‑tube SM G.652.D/G.657.A1 |

24–144F; PE sheath; dielectric; rated tensile ≥2–6 kN |

km |

Feeder route length × (1.02–1.05) |

Add 2–5% waste |

|

2 |

Distribution Cable |

12–96F OSP/indoor‑outdoor cable |

LSZH (indoor), PE (outdoor); bend radius ≥10×OD |

km |

Distribution routes × (1.03) |

Spare 10–20% fibers |

|

3 |

Drop Cable |

1–4F G.657.A2 drop (flat/round) |

Outdoor PE/LSZH indoor; SC/APC pigtail |

km |

Avg. drop length × HH × (1.05) |

HH = homes passed/connected |

|

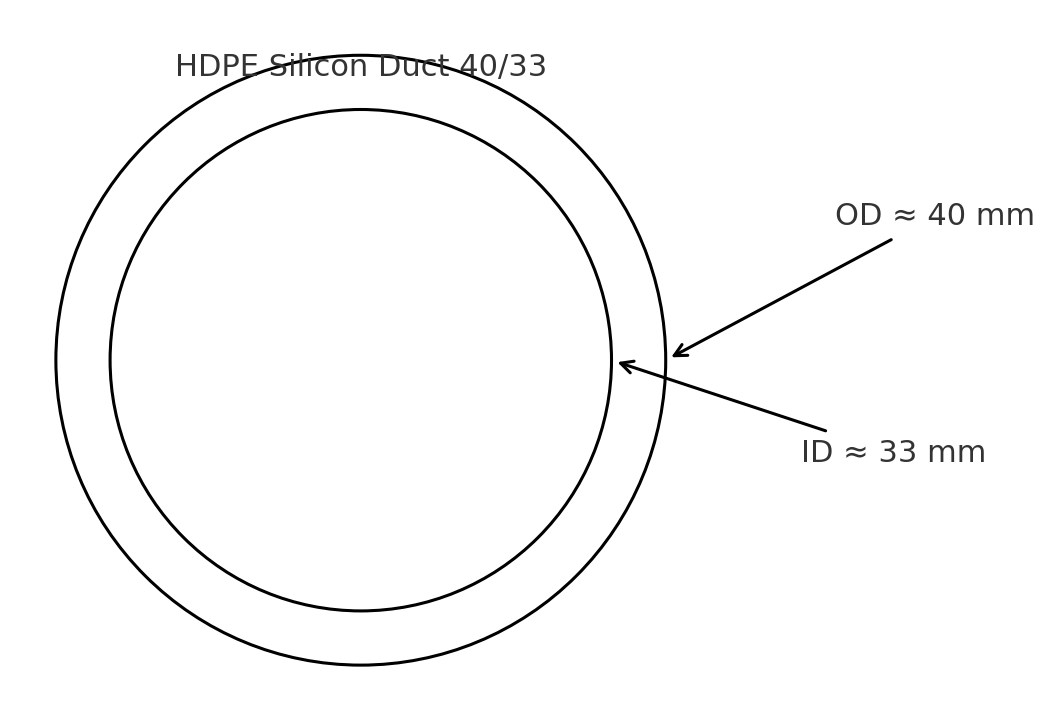

4 |

Micro‑duct / HDPE Duct |

HDPE silicon 40/33 mm + accessories |

Pressure‑rated; UV‑resistant; colored stripes |

km |

Civil routes × (1.02) |

Couplers/bends included |

|

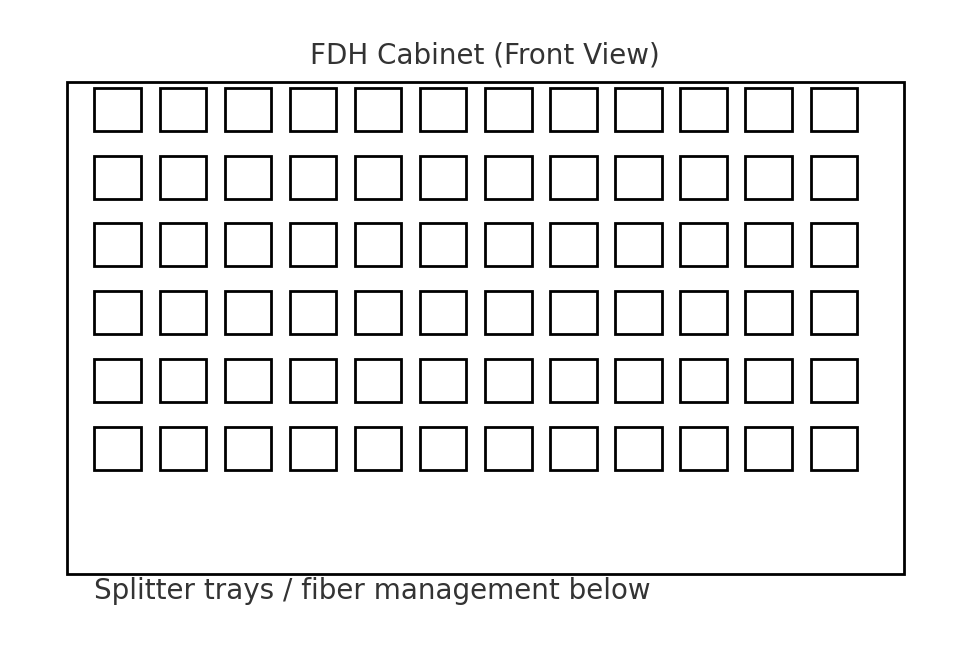

5 |

FDH Cabinet |

Outdoor splitter cabinet |

IP54+; 144–576F capacity; lockable |

pcs |

By area take‑rate |

Room for growth 20–30% |

|

6 |

Splitters |

PLC 1:8 / 1:16 / 1:32 / 1:64 |

≤0.2 dB uniformity; ≤0.3 dB PD loss variance |

pcs |

Ports per FDH × split plan |

SC/APC or bare |

|

7 |

Closures |

Dome / In‑line fiber joint closures |

IP68; 24–144F; heat‑shrink or mechanical |

pcs |

Splice points × (1.1) |

Include trays |

|

8 |

Boxes |

Wall‑mount distribution/CTO boxes |

4–16 ports; SC/APC; LSZH |

pcs |

Access points |

Room for expansion |

|

9 |

ODF/Panels |

19" ODF, patch panels, MPO/LC patching |

LC/SC adapters; cable mgmt |

pcs |

CO & hub counts |

Include pigtails & cords |

|

10 |

Connectors & Pigtails |

SC/APC, LC/UPC cords |

≤0.2 dB insertion; ≥55 dB return (APC) |

pcs |

Per ONT + spares 5–10% |

Field/Factory |

|

11 |

Hardware |

Stainless strap, band‑it buckles, clamps |

304/316 S/S |

set |

Per pole/closure |

Corrosion‑resistant |

|

12 |

Tools |

Fusion splicer, cleaver, OTDR, power meter |

Core alignment; 1310/1550 nm |

set |

Per crew |

Calibration certs |

|

13 |

Consumables |

Splice sleeves, alcohol wipes, tags |

Spec‑grade |

lot |

Per 100 splices |

Add buffer 10% |

1) ISO 9001/14001/45001 or equivalent; RoHS/REACH compliance for materials.

2) Conformity to ITU‑T G.652.D/G.657.A1/A2, IEC 60794, IEC 61753/61754, GR‑326/GR‑1209/GR‑1221 where applicable.

3) Traceable test reports (factory OTDR, insertion/return loss, environmental tests).

4) Proven projects in similar climates (UV, high humidity, coastal salt‑spray).

5) Lead‑time commitments, safety stock options, and RMA policy ≤1% DOA.

6) Export‑ready packing; drum handling specs; barcoding for WMS integration.

Factory: type/routine/sample tests per IEC/GR; incoming inspection (AQL); dimensional checks; fiber ID verification.

Site: closure sealing, splice loss ≤0.1–0.2 dB, connector IL ≤0.3 dB (SC/APC), ORL ≥55 dB, OTDR 1310/1550 nm, end‑to‑end power, PON service activation tests.

• Incoterms EXW/FOB/CIF/DDP as negotiated

• Fumigated reels/crates, moisture barrier, impact indicators

• Labels: project code, drum no., fiber count/length, G/N weight, handling symbols

• Staggered deliveries by build zone to minimize yard congestion

• Datasheets & MSDS; FAT reports; OTDR/IL/ORL records; closure maps; as‑built drawings (GIS/KML)

• Handover: optical budget, test certificates, warranty, spares list

|

Test |

Method |

Acceptance Criteria |

|

OTDR (1310/1550 nm) |

Bi‑directional trace per span |

Match design; no unexplained events; within budget |

|

Insertion/Return Loss |

OLTS / LS & PM |

IL ≤0.3 dB per connector; ORL ≥55 dB (APC) |

|

Splice Loss |

OTDR/events |

≤0.1–0.2 dB per splice |

|

Continuity/Polarity |

VFL & mapping |

Correct mapping; no cross |

|

Service Test |

IP throughput/latency/jitter |

Per SLA (e.g., 1 Gbps DS, <5 ms access) |

|

Risk |

Impact |

Mitigation |

|

Permit delays |

Schedule slip |

Early authority engagement; parallelize materials prep |

|

Supply lead‑time |

Build idle time |

Dual‑source critical items; buffer stock |

|

ROW conflicts |

Re‑routing |

Alternate routes pre‑approved; HDD/micro‑trenching |

|

Weather |

Productivity loss |

Seasonal scheduling; heat/rain plans |

|

Fiber damage |

Rework cost |

Training; protective sheathing; clear tagging |

• Payment: 30% advance at PO; 60% against shipment docs; 10% after site acceptance (or LC at sight)

• Schedule: T0 PO; T0+2w FAT; T0+4–6w first shipment; weekly deliveries; completion T0+16–24w

Feeder = Σ(feeder routes) × (1.02–1.05)

Distribution = Σ(distribution routes) × 1.03

Drop = Avg. drop length × Homes connected × 1.05

Splitters = Homes served ÷ Users per PON port × design reserve

Closures = Splice points × 1.1

Ducts = Civil length × 1.02 + fittings

Assume XGS‑PON N2 (budget ~31–33 dB). Example path adds: fiber attenuation, splitter loss, splices, connectors, and margin. Reduce split, shorten route, or raise optics class if the total loss exceeds the budget.

• ADSS & duct‑grade OSP (SM G.652.D/G.657.A1/A2)

• HDPE silicon ducts (e.g., 40/33 mm) & fittings

• PLC splitters, FDH cabinets, closures, CTO/distribution boxes

• Patch cords & pigtails (SC/APC, LC/UPC), ODF/patch panels (incl. MPO)

• Accessories: stainless straps & band‑it buckles, clamps

• Tools & test kits: fusion splicer, cleaver, OTDR, OLTS, microscope

Contact: chulinxie@shenzhou-cables.cn | https://shenzhou-cables.cn | +86 15818462024

Figure 1. End‑to‑end FTTH topology (OLT → FDH/splitter → ONT).

Figure 2. HDPE silicon duct 40/33 mm cross‑section (schematic).

Figure 3. ADSS cable layered structure (schematic).

Figure 4. FDH cabinet front‑panel port map (illustrative).

Figure 5. Fiber joint closure with stacked splice trays (illustrative).

For product drawings & datasheets: contact Shenzhou Cables — chulinxie@shenzhou-cables.cn

Screenshot, WeChat Scan QR Code

WeChat ID: +86 15818462024

(Click to copy WeChat ID, add as friend)