Release Date: 2025-11-06 View Count:

Data Center (Server Room) Procurement Plan & Structure — Shenzhou Cables

A practical guide for designing, sourcing, and validating a resilient, scalable data room (Tier II–III)

This document presents a complete procurement strategy and a reference structure for a modern data room. It focuses on standardized racks, dual‑path power, hot/cold aisle containment, structured cabling (single‑mode & OM4), and monitoring for uptime. The plan is aligned with common industry practices (TIA‑942, ISO/IEC 11801) and leverages Shenzhou Cables’ fiber cabling portfolio.

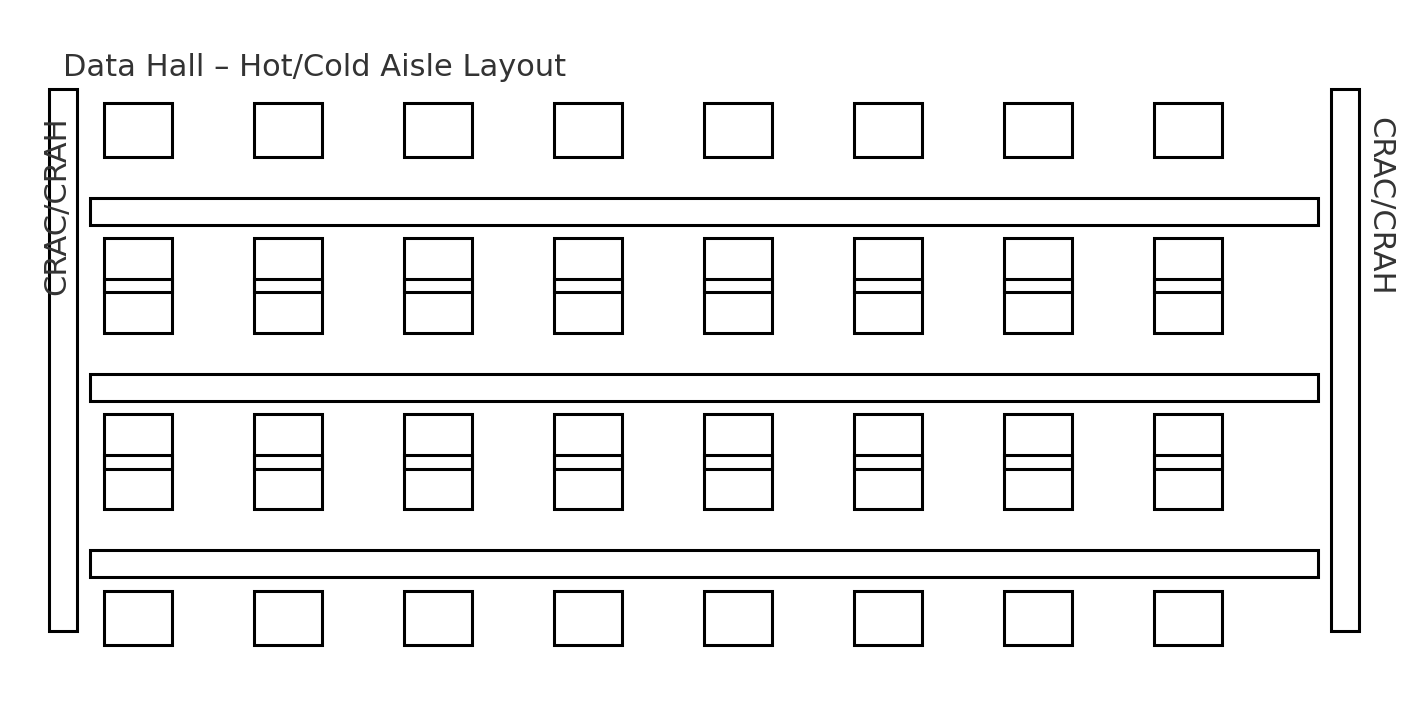

Figure 1. Data hall hot/cold aisle layout with CRAC/CRAH (schematic).

• Hot/cold aisle or containment; blanking panels and brush grommets to reduce bypass air

• CRAC/CRAH sizing by heat load; N+1 redundancy; raised‑floor optional for under‑floor air delivery

• Overhead ladder racks; separation of power and data

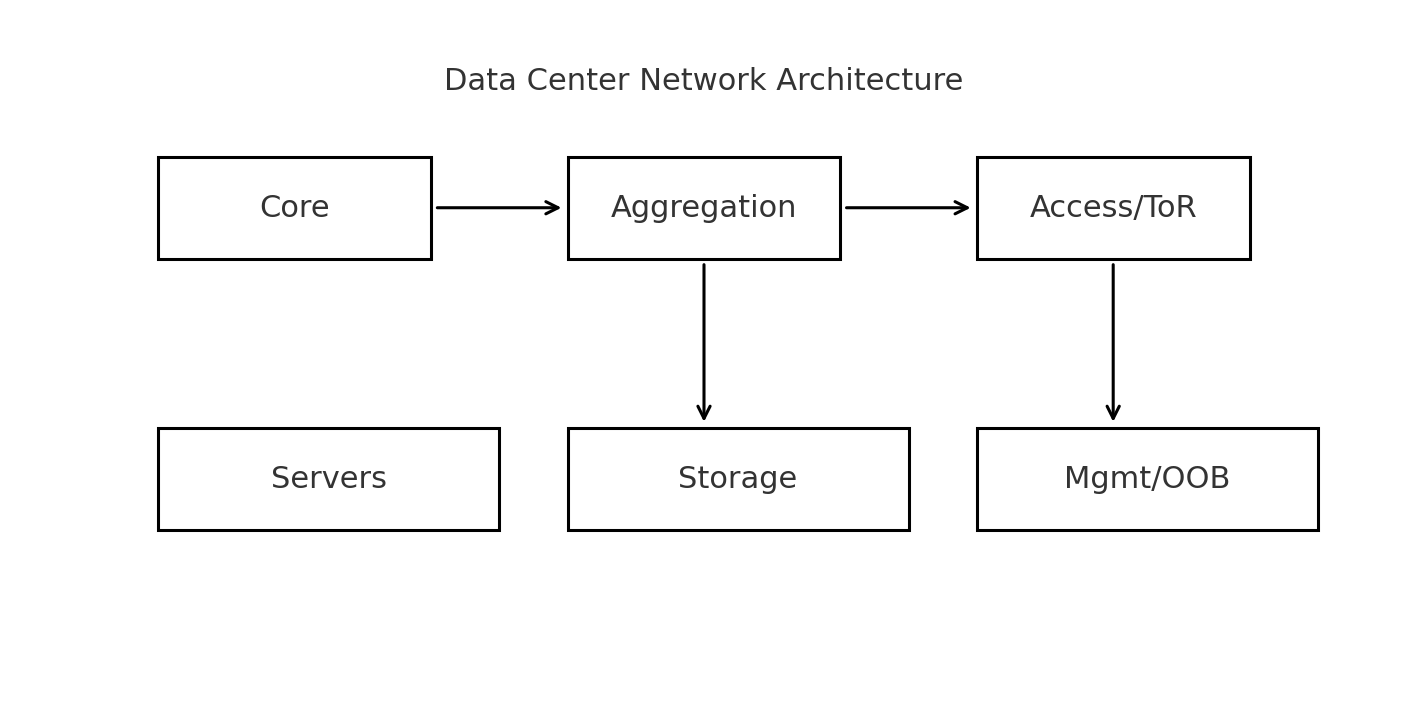

• Core/Spine → Aggregation/Leaf → Access/ToR; redundant uplinks; MLAG/VPC where applicable

• OOB/management network physically separated; dedicated KVM/IPMI

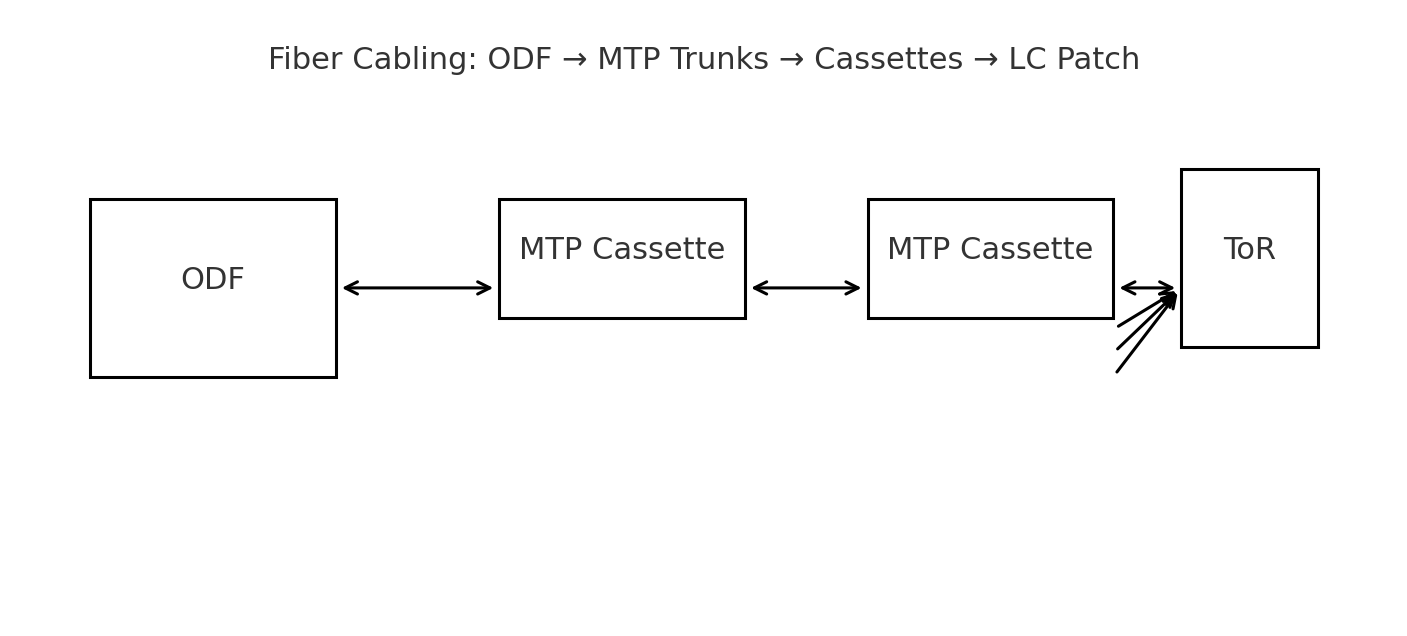

• Structured fiber: MTP trunks to cassettes; LC patch cords to servers; standard lengths and polarity mapping

Figure 2. Core/Aggregation/Access network blocks with ToR.

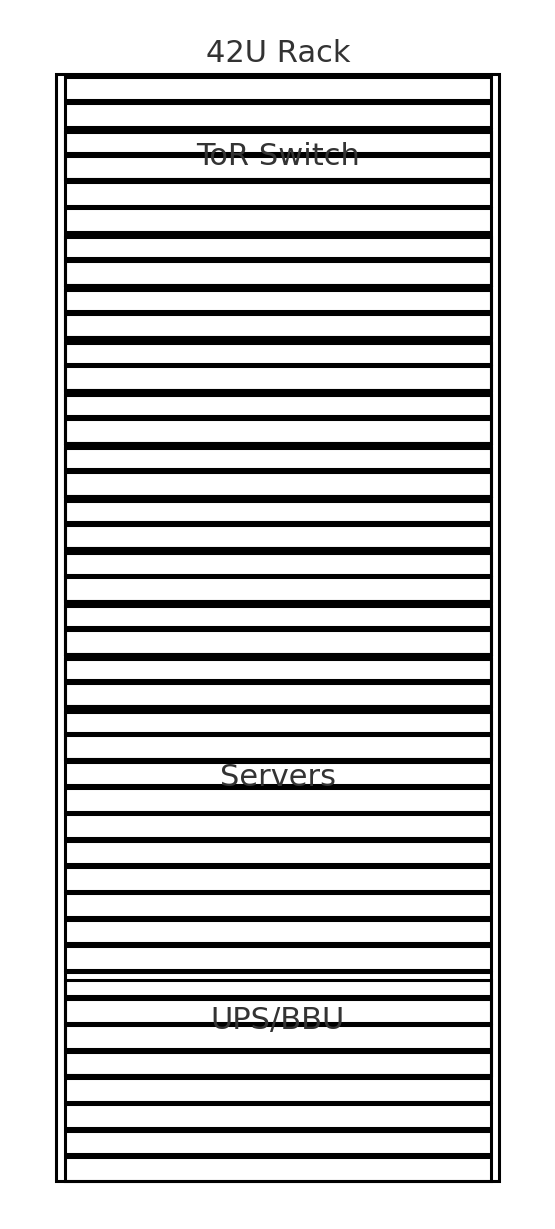

• 42U/45U racks with front/rear cable managers; rails and grounding kits

• MPO/MTP trunk cables (OM4/SM) to modular cassettes; LC/SC patch cords to endpoints

• ODF/patch panels at MMR/IDF; color‑coded labeling for SM vs MM

• Copper: Cat6A for management and specific workloads (PoE, OOB)

Figure 3. 42U rack elevation with ToR switch, servers, and UPS/BBU location.

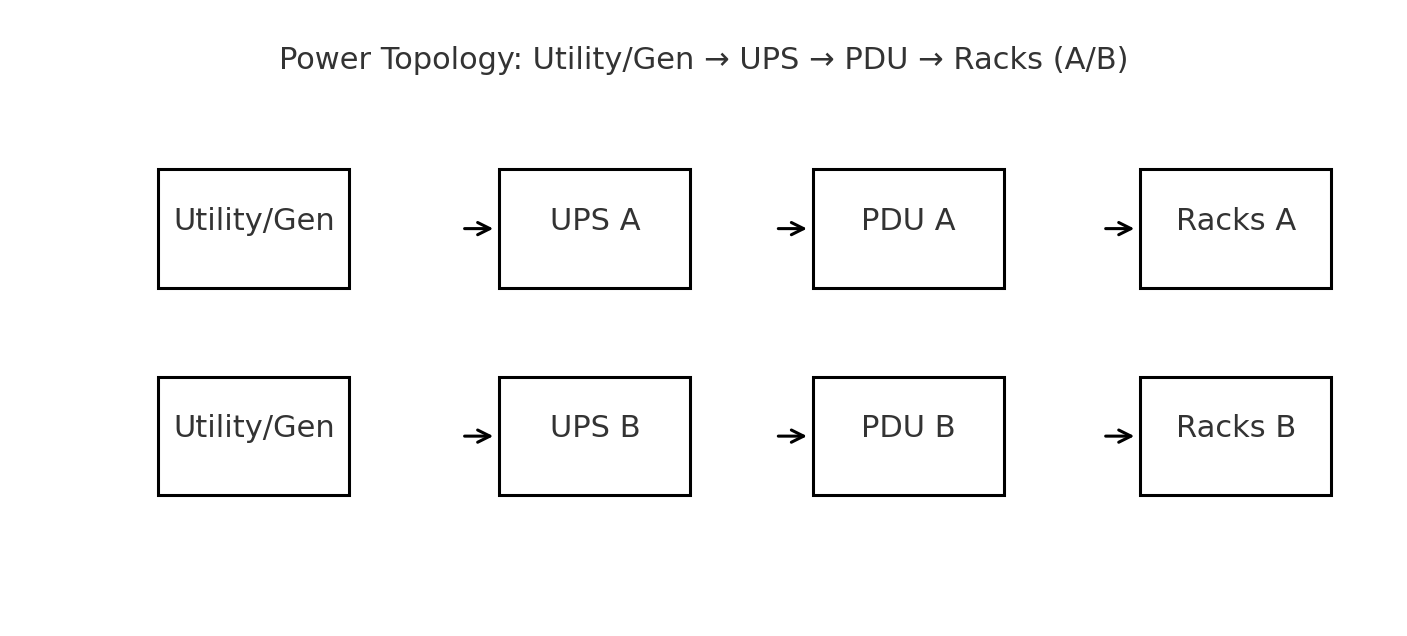

• Dual A/B power feeds from UPS to PDUs; selective transfer switches (STS) as required

• Proper bonding to grounding grid; surge protection

• Battery autonomy sized to ride‑through generator start; graceful shutdown policies

Figure 4. Dual‑path power from Utility/Gen to UPS → PDU → racks (A/B feeds).

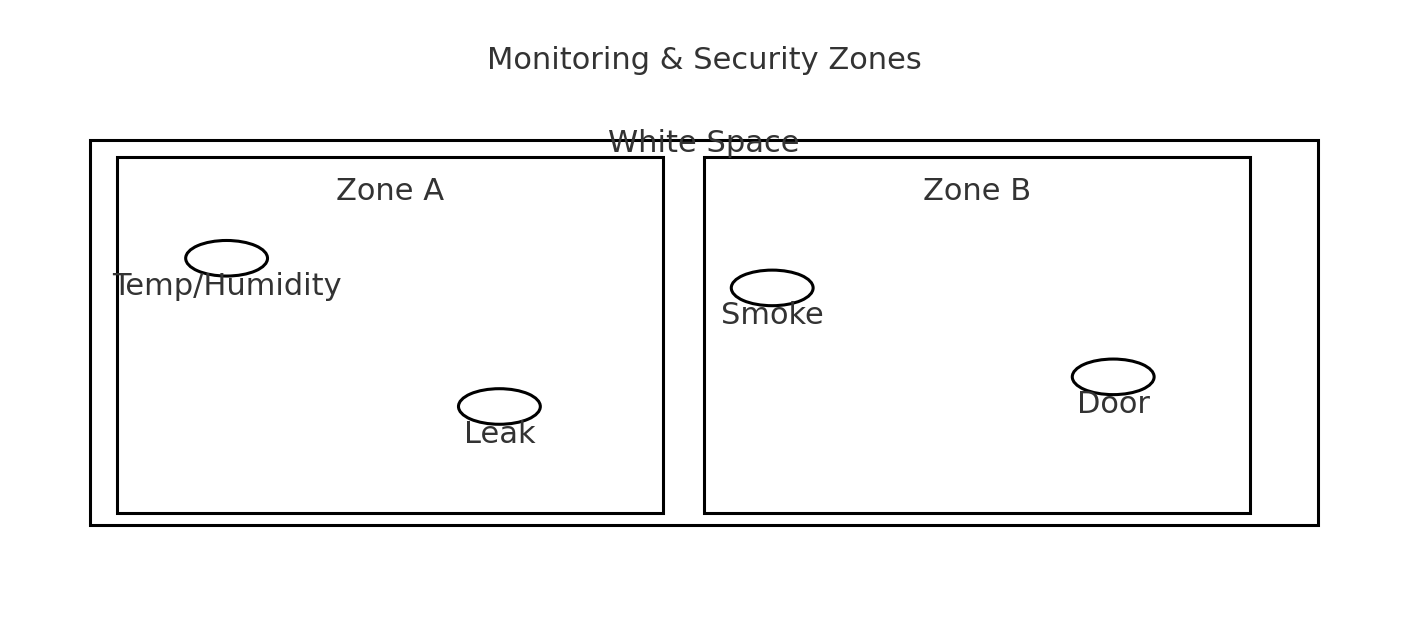

• Environmental: temperature, humidity, differential pressure, leak detection

• Fire: early smoke detection, clean‑agent suppression (e.g., FK‑5‑1‑12)

• Access Control: zones with badges/biometrics; CCTV and audit logging

Figure 5. Environmental sensors and security zoning (illustrative).

• Single‑mode (G.652.D/G.657.A1) for longer interconnects/MMR; OM4 MM for ToR links

• Polarity Method B or equivalent; document trunks/cassettes; test at 850/1300 nm (MM) and 1310/1550 nm (SM)

Figure 6. ODF → MTP trunks → cassettes → LC fan‑out towards ToR.

WP1 Racks & Accessories; WP2 Fiber Cabling System; WP3 Copper Cabling; WP4 Power & PDUs; WP5 Cooling; WP6 Fire & Security; WP7 Tools & Test; WP8 Documentation & Training.

Core line items with example specifications and quantity formulas:

No. | Category | Item / Description | Key Specs | Unit | Est. Qty (Formula) | Notes |

1 | Racks | 42U rack with accessories | 800×1000 mm; cable mgmt; grounding | pcs | Rows×Racks/row | Blanking panels incl. |

2 | ODF/Panels | 19" ODF, MPO panels/cassettes | LC/SC adapters; MPO‑LC cassettes | pcs | Per MMR/IDF | Labeling kit |

3 | Fiber Trunks | MTP/MPO trunk (OM4/SM) | 12/24‑fiber; polarity Method B | pcs | Paths×Len groups | Factory‑terminated |

4 | Patch Cords | LC‑LC (SM/OM4), Cat6A | ≤0.3 dB IL (fiber); 24 AWG (copper) | pcs | Ports×(1.1–1.2) | Spare 10–20% |

5 | Closures/Boxes | Fiber splice closures, boxes | IP54–IP68 as area demands | pcs | Splice points×1.1 | Trays included |

6 | PDUs | Metered/switched PDUs | A/B feeds; IEC C13/C19 mix | pcs | Racks×2 | Networked metering |

7 | UPS | Online double‑conversion | N+1; SNMP; runtime calc | pcs | By power tier | Battery strings incl. |

8 | Cooling | CRAC/CRAH or In‑row | N+1; EC fans; control | pcs | By heat load | Containment optional |

9 | Security/Fire | ACS, CCTV, ESD, suppression | Clean‑agent; VESDA | set | Per room | Integration w/ BMS |

10 | Tools/Test | OTDR, OLTS, microscope | 1310/1550; 850/1300; IEC 61300 | set | Per crew | Calibration certs |

• ISO 9001/14001/45001; RoHS/REACH compliance for materials.

• Conformance: ISO/IEC 11801, TIA‑942, IEC 61754, IEC 61300; fiber G.652.D/G.657.A1; OM4 MMF.

• Factory test reports (IL/ORL), OTDR samples; serialized labeling and barcodes.

• Proven deployments; SLA support; RMA ≤1% DOA; spare parts policy.

Factory: routine/type tests for cables and cassettes; connector IL ≤0.3 dB (LC), ORL ≥55 dB (APC). Site: pathway inspection; OTDR 1310/1550 (SM) and 850/1300 (MM); OLTS certification per link; labeling/audit; power failover test (A/B feed, UPS runtime), hot/cold aisle pressure check.

Export‑grade crates and reels; moisture barrier; impact indicators; QR‑coded labels with BOM mapping; staggered deliveries aligned to fit‑out phases; returnable reels when feasible.

• Lead‑time volatility → lock forecast; safety stock for MTP trunks and cassettes

• Workface clashes → weekly coordination with GC/MEP; pre‑pull approvals

• Heat load creep → scalable cooling blocks; capacity headroom ≥20%

• Cable damage → protected pathways; trained crews; inspection hold points

MTP Trunks = Σ(row‑to‑MMR distance groups) × strands bundle count

LC Patch Cords = Active ports × (1.1–1.2) spare factor

Racks = Total devices U / 36–38U usable per rack (allowing space)

PDUs = Racks × 2 (A/B feeds)

UPS kVA = IT load × (1.2–1.3) / efficiency

CRAC/CRAH Units = IT load (kW) / unit capacity × (N+1)

• MPO/MTP trunks and cassettes (OM4 & SM), LC/SC patch cords and pigtails

• ODFs, fiber patch panels, rack‑mount cable management

• Fiber closures and distribution boxes for MMR/IDF hand‑offs

• Stainless steel bands & buckles, clamps, pathway accessories

• Tooling & test kits: fusion splicer, cleaver, OTDR, OLTS, microscope

Contact: chulinxie@shenzhou-cables.cn | https://shenzhou-cables.cn | +86 15818462024

Screenshot, WeChat Scan QR Code

WeChat ID: +86 15818462024

(Click to copy WeChat ID, add as friend)