Release Date: 2025-11-06 View Count:

Cables Procurement Plan & Structured Cabling Architecture — Shenzhou Cables

A practical, standards‑aligned blueprint for enterprise campuses, office towers, and data halls

Executive Overview

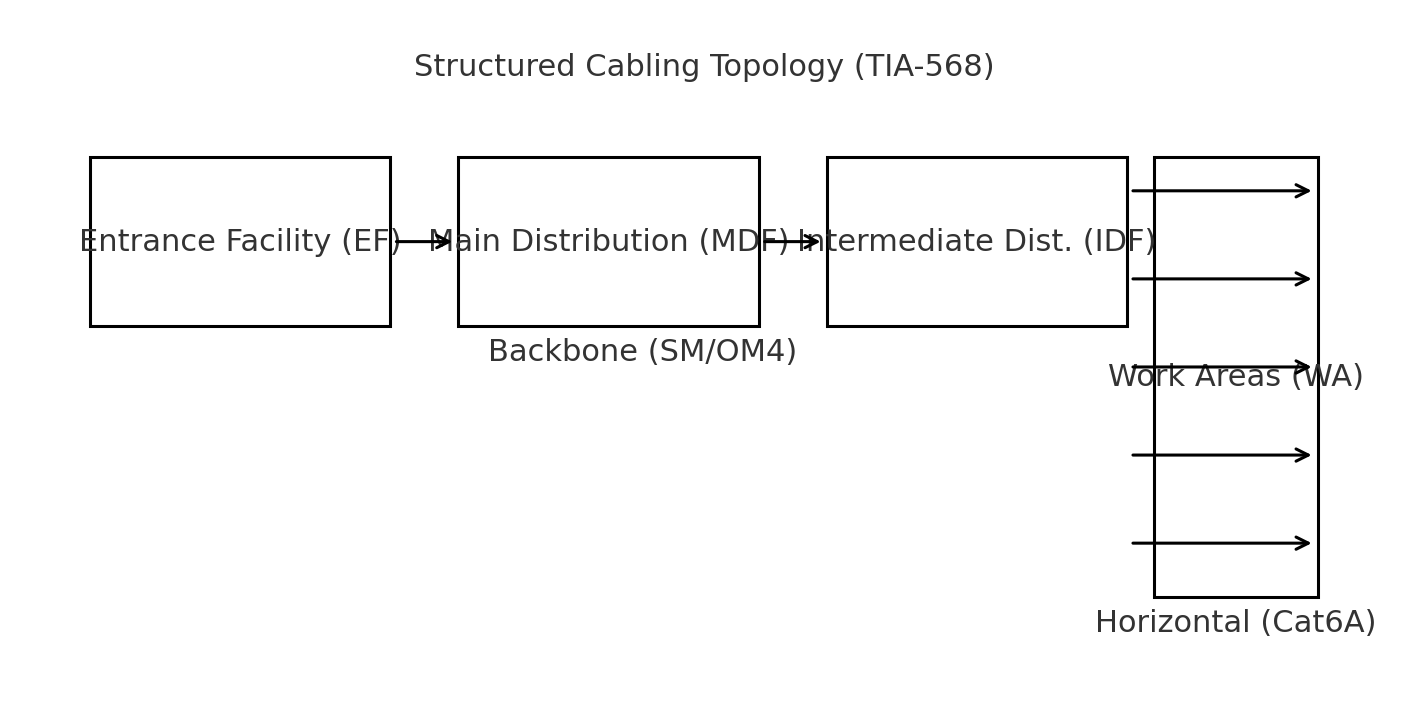

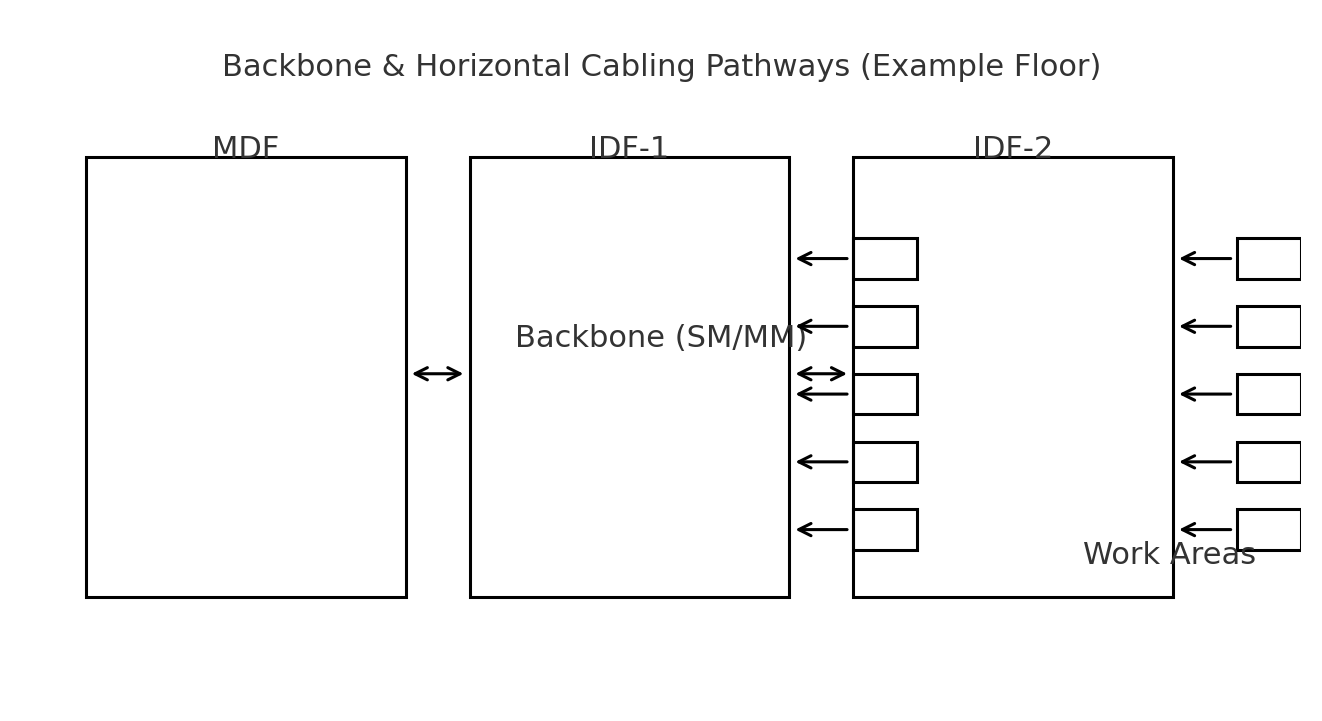

This document defines a complete procurement plan and a reference structured cabling architecture covering fiber and copper systems. It follows TIA‑568 and ISO/IEC 11801 principles, with a hierarchical topology from the Entrance Facility (EF) to the Main Distribution (MDF) and Intermediate Distribution (IDF) rooms, down to Work Areas (WA). The plan emphasizes standards compliance, lifecycle cost reduction, and ease of expansion.

Figure 1. Structured cabling topology from EF → MDF → IDF → Work Areas (TIA‑568).

• Backbone: single‑mode (G.652.D/G.657.A1) for campus/vertical risers; OM4 for short‑reach interconnects

• Horizontal: Cat6A copper to outlets; optional fiber to desk for special workloads

• Demarcation: ODF at EF/MDF; IDF per floor/zone; patch panels and cable managers in all rooms

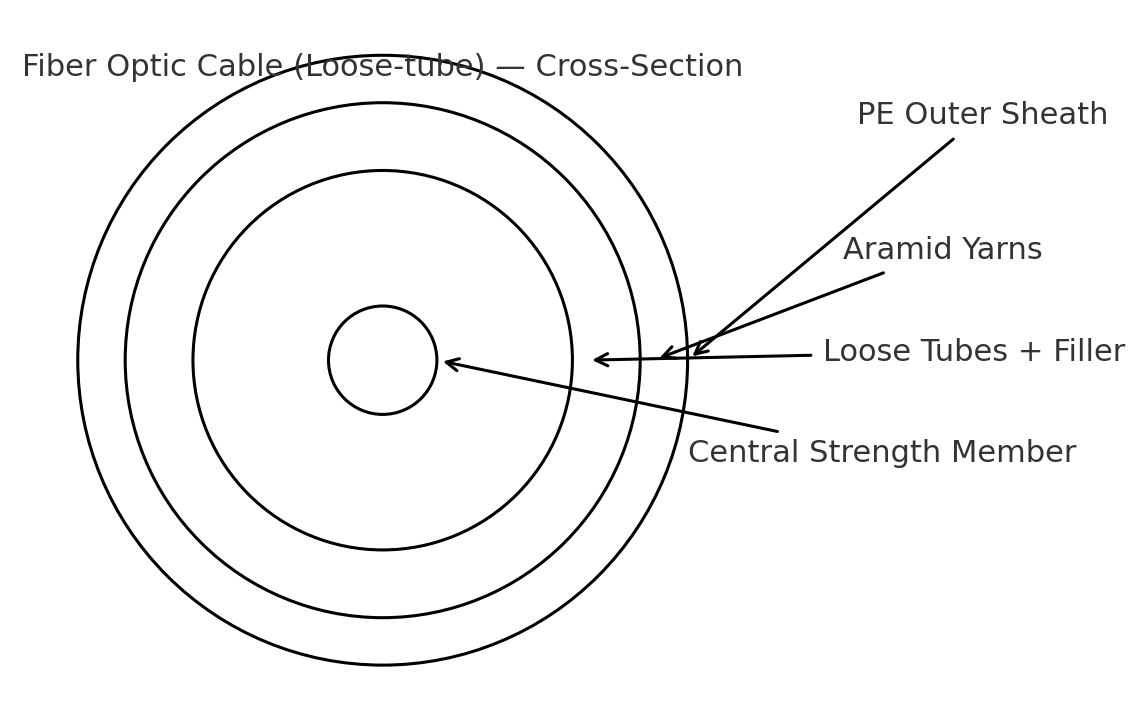

• Fiber: SM G.652.D/G.657.A1 for long runs; OM4 MM for high‑density short‑reach; connectors SC/APC (PON) or LC/UPC (enterprise)

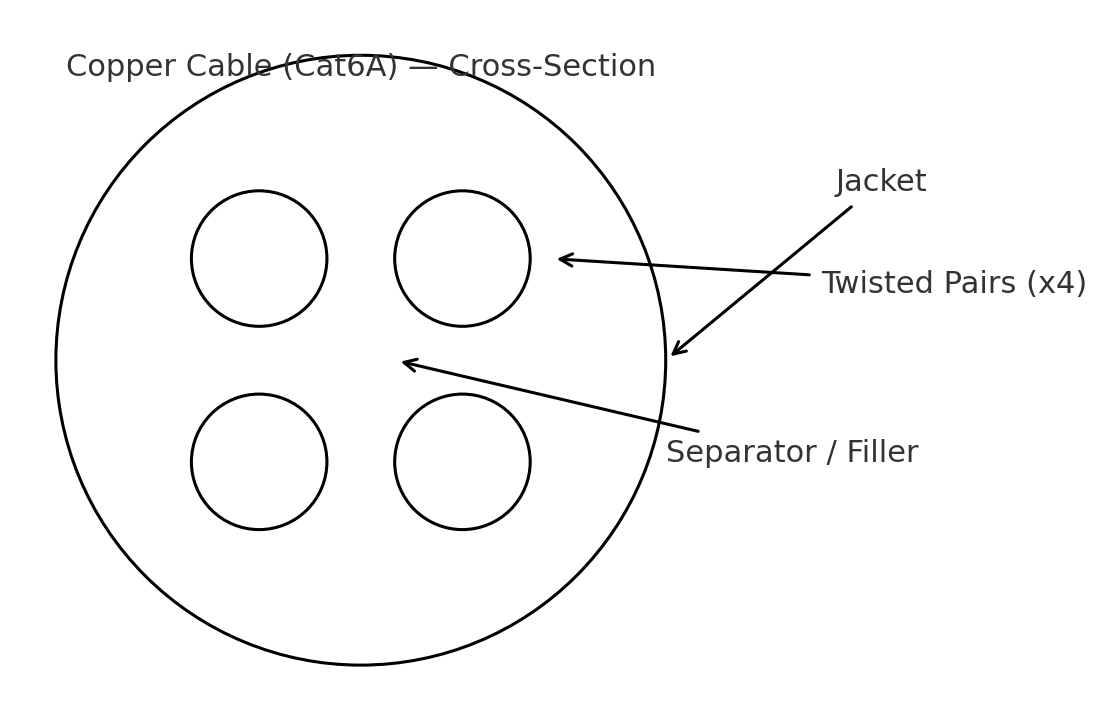

• Copper: Cat6A U/FTP or F/UTP; channel up to 100 m; PoE++ readiness; permanent link certification per TIA

• Pathways: ladder racks, trays, raceways; separation of power and data; bend‑radius control

Figure 2. Fiber loose‑tube cable — illustrative cross‑section.

Figure 3. Cat6A copper cable — illustrative cross‑section.

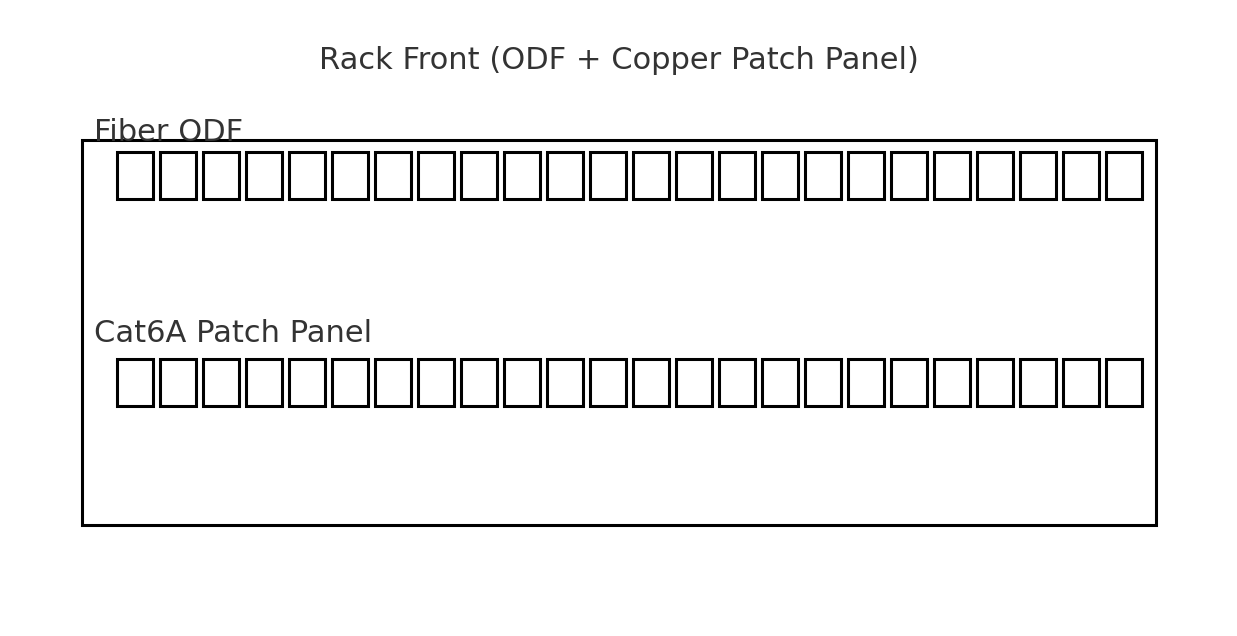

• EF/MDF: ODFs, copper patch panels, grounding; environmental control and access security

• IDF: per‑floor distribution; fiber/copper termination; cable managers; labeling and documentation

• WA: TO (telecom outlets) with Cat6A; optional fiber outlets for labs or media suites

Figure 4. Rack front with fiber ODF and Cat6A patch panel (illustrative).

• Backbone EF→MDF→IDFs via risers; redundant diverse routes where feasible

• Horizontal IDF→WAs via trays/raised floor; consolidation points where required

• Labeling: room‑rack‑U‑port conventions; QR code mapping to drawings

Figure 5. Example pathways — backbone and horizontal distribution to work areas.

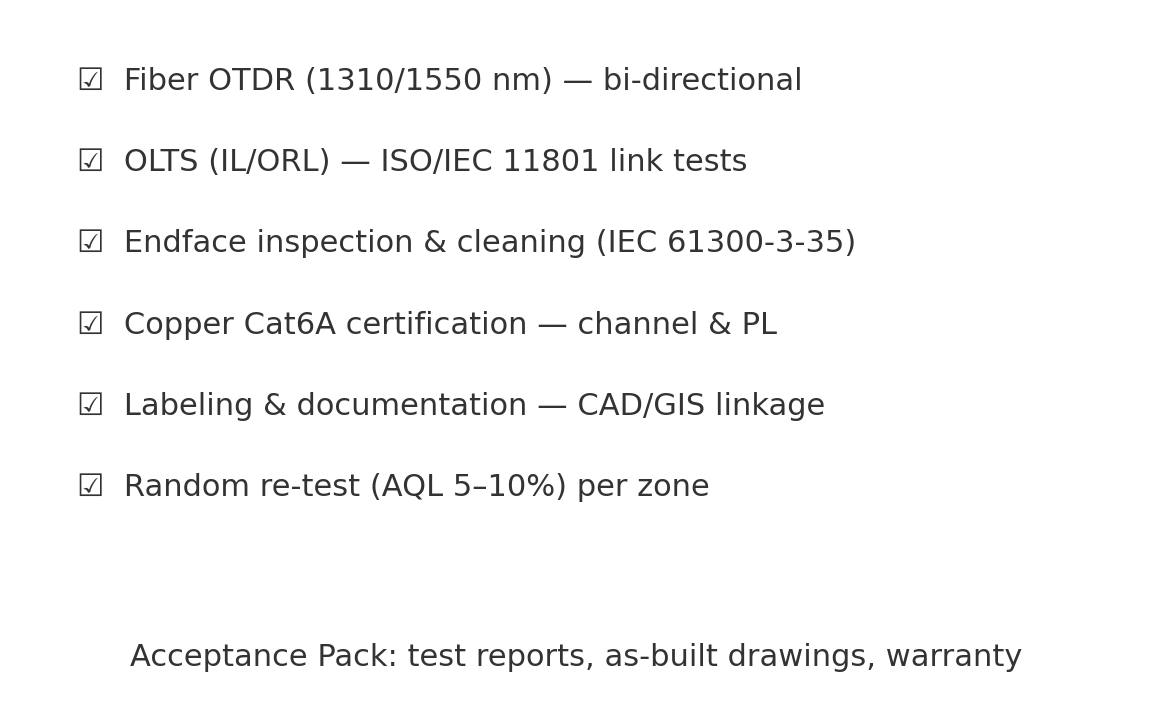

Fiber: OTDR bi‑directional at 1310/1550 nm; OLTS IL/ORL; endface inspection. Copper: DSX‑class certification for Cat6A; channel and permanent link. Deliverables: test reports, as‑built drawings (CAD/GIS), and warranty letters.

Figure 6. QA/QC acceptance checklist for fiber and copper links.

WP1 Fiber System; WP2 Copper System; WP3 Pathways & Racks; WP4 Active Interfaces (transceivers); WP5 Tools & Test Kits; WP6 Documentation & Training; WP7 Logistics & Packaging.

Core line items and example specifications (quantities by formulas in Section 11):

No. | Category | Item / Description | Key Specs | Unit | Est. Qty (Formula) | Notes |

1 | Backbone Fiber | SM G.652.D/G.657.A1 loose‑tube | 12–144F; PE/LSZH; OS2 | km | Route length × (1.02–1.05) | Spare fibers 20% |

2 | OM4 Fiber | Indoor/outdoor MM trunks | MTP/MPO 12/24F; cassettes | pcs | Paths × bundles | Factory‑terminated |

3 | ODF/Panels | 19" ODF, MPO panels | LC/SC; cable mgmt | pcs | EF/MDF/IDF count | Labeling kit |

4 | Horizontal Copper | Cat6A U/FTP/F/UTP | Channel ≤100 m; PoE++ | m | Avg. run × outlets ×1.05 | Include slack |

5 | Patch Cords | LC‑LC (SM/OM4), Cat6A | IL ≤0.3 dB (fiber) | pcs | Ports × (1.1–1.2) | Spare 10–20% |

6 | Hardware | Racks, managers, trays | 42U racks; ladder racks | pcs | By rooms/rows | Grounding kits |

7 | Closures/Boxes | Fiber closures, WA outlets | IP54–68; 1–4 ports | pcs | Splice points / outlets | Trays incl. |

8 | Accessories | Straps, buckles, labels | 304/316 S/S; tags | lot | Per 100 terminations | |

9 | Tools/Test | OTDR, OLTS, DSX | Calibrated; 1310/1550; 850/1300 | set | Per crew | Certs required |

• ISO 9001/14001/45001; RoHS/REACH for materials.

• Compliance: TIA‑568, ISO/IEC 11801; fiber G.652.D/G.657.A1; OM4; connectors per IEC 61754.

• Factory tests (IL/ORL, geometry); serialized labels and barcodes; change control and CoC.

• Proven references; RMA ≤1% DOA; spare parts program; technical training support.

• Incoming: visual, geometry, test certificates verification (AQL).

• Installation: pathway inspection, bend‑radius control, termination workmanship.

• Testing: fiber OTDR + OLTS; copper DSX certification. Deliver reports and remedy non‑conformities.

Export‑grade reels/crates; moisture barrier; impact indicators; QR codes tied to BOM; staged deliveries per floor/zone.

Backbone Fiber = Σ(backbone routes) × (1.02–1.05)

Horizontal Copper = Avg. run length × (# outlets) × 1.05

MPO Trunks = Σ(distance groups) × bundle count (12/24F)

Patch Cords = Active ports × (1.1–1.2)

Racks = Total U / 36–38U usable per rack

Closures/Boxes = Splice points × 1.1; Outlets per WA

• SM/OM4 fiber cables, MPO trunks & cassettes, LC/SC patch cords

• Cat6A copper cables, patch panels, outlets, and cords

• ODFs, distribution boxes, closures, racks, cable pathways

• Accessories: stainless straps & band‑it buckles, labels, clamps

• Tools & test kits: fusion splicer, cleaver, OTDR, OLTS, copper certifier

Contact: chulinxie@shenzhou-cables.cn | https://shenzhou-cables.cn | +86 15818462024

Screenshot, WeChat Scan QR Code

WeChat ID: +86 15818462024

(Click to copy WeChat ID, add as friend)